Oil Polishing Unit Manufacturing

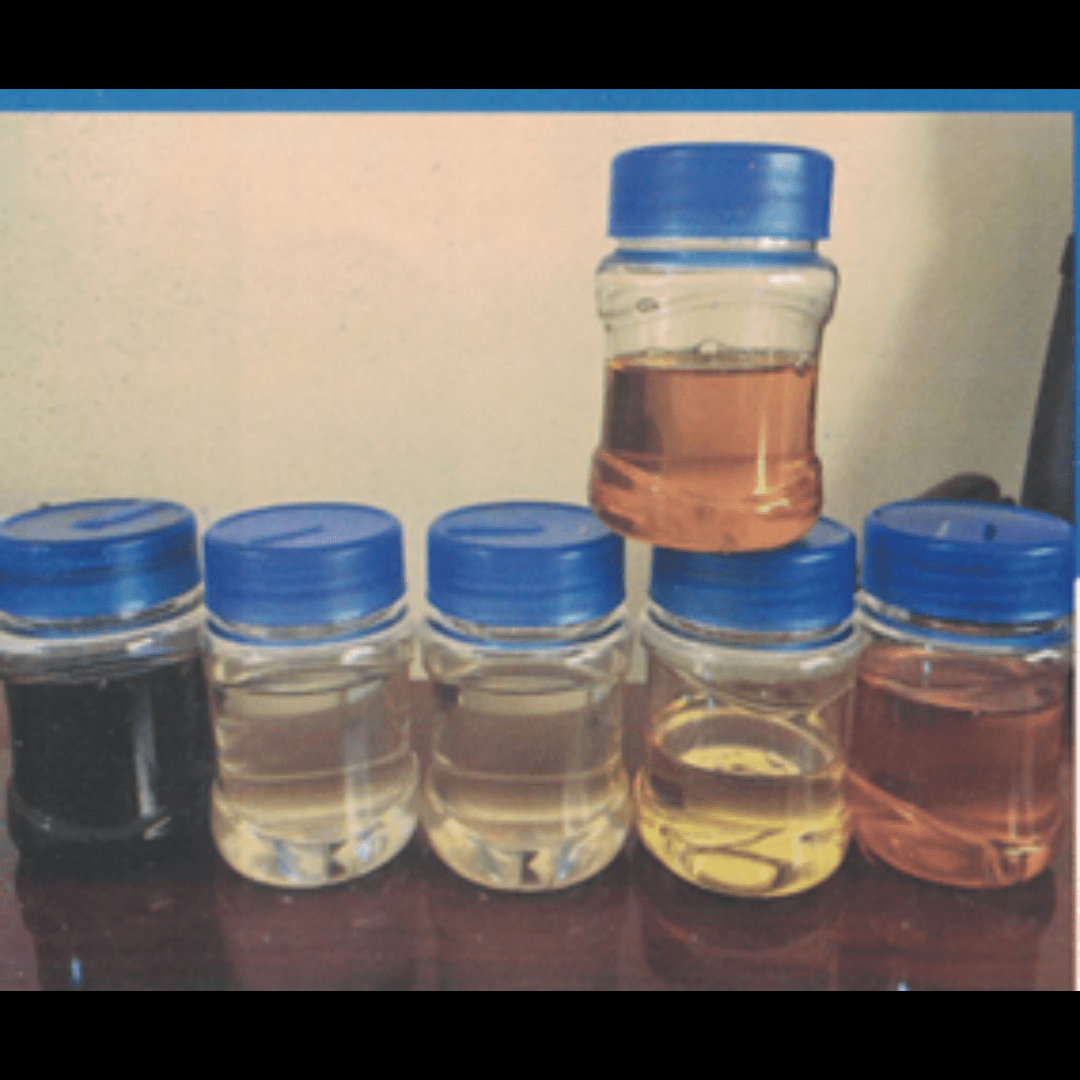

At Innovative PetroChem India, we specialize in the manufacturing of advanced oil polishing units designed to enhance the quality of various oils by removing unwanted colour and odour. Since April 2017, we have been delivering media-based filtration systems that offer a superior alternative to traditional clay-based methods. Our units are engineered for high efficiency, cost-effectiveness, and ease of use, making them ideal for both small-scale and large-scale industrial applications. Backed by innovation and performance, our polishing units ensure cleaner, purer oil with minimal product loss and long-lasting media life.

General Process Description

Oil filtration by Activated media is a final polishing process in re-refining of used oil. The process consists of small adsorption column loaded with a bed of activated media. Generally. distilled oil feeds to the top of the media bed and purified oil is collected from the bottom of the column. Once, the breakthrough achieved means activated media has exhausted, Need to go for reactivation of media. In-situ reactivation consists of two major processes. Activated Media can be used more than 150 cycles up to 250 cycles, depends on inlet quality of oil.

A Perfect Replacement for Clay-Based Filter Press

The adsorbent-based oil polishing unit is an ideal solution for removing colour and odour by effectively eliminating unsaturated hydrocarbons, sulfur, VOCs (Volatile Organic Compounds), and polar compounds. This unit serves as a superior alternative to traditional clay-based filtration systems, offering enhanced performance, cost-efficiency, and ease of operation.

Suitable Oils for Polishing:

Distilled Oil – SN150 / SN300

Motor Oil

Vegetable Oil

Edible Oil

1. Reactivation

To begin the reactivation process, stop the oil flow and purge as much hydrocarbon from the media as possible. In-situ thermal reactivation is then carried out by heating the media under controlled temperature conditions. It is crucial to avoid overheating, as prolonged exposure to high temperatures can damage the active surface area of the media, reducing its effectiveness.

Once the thermal treatment is complete, the media must be cooled down to approximately 80°C before resuming the polishing operation. This cooling can be efficiently achieved using dry air circulation to ensure the media is stabilized for reuse.

2. Regeneration of Oil

Before oil enters the polishing unit, it must be heated or cooled to around 80°C, depending on its current state. This step is essential to prepare the oil for optimal adsorption efficiency. The regeneration process involves passing this pre-treated oil through the activated media columns, where colour and odour are effectively removed. This results in a refined, colourless, and odourless product, suitable for high-quality industrial reuse.

Other Major Polishing Unit

Wax Polishing Units

Transformer Oil Polishing Unit

Diesel Polishing Unit

Pyrolysis oil Polishing Unit